From Concept To Reality

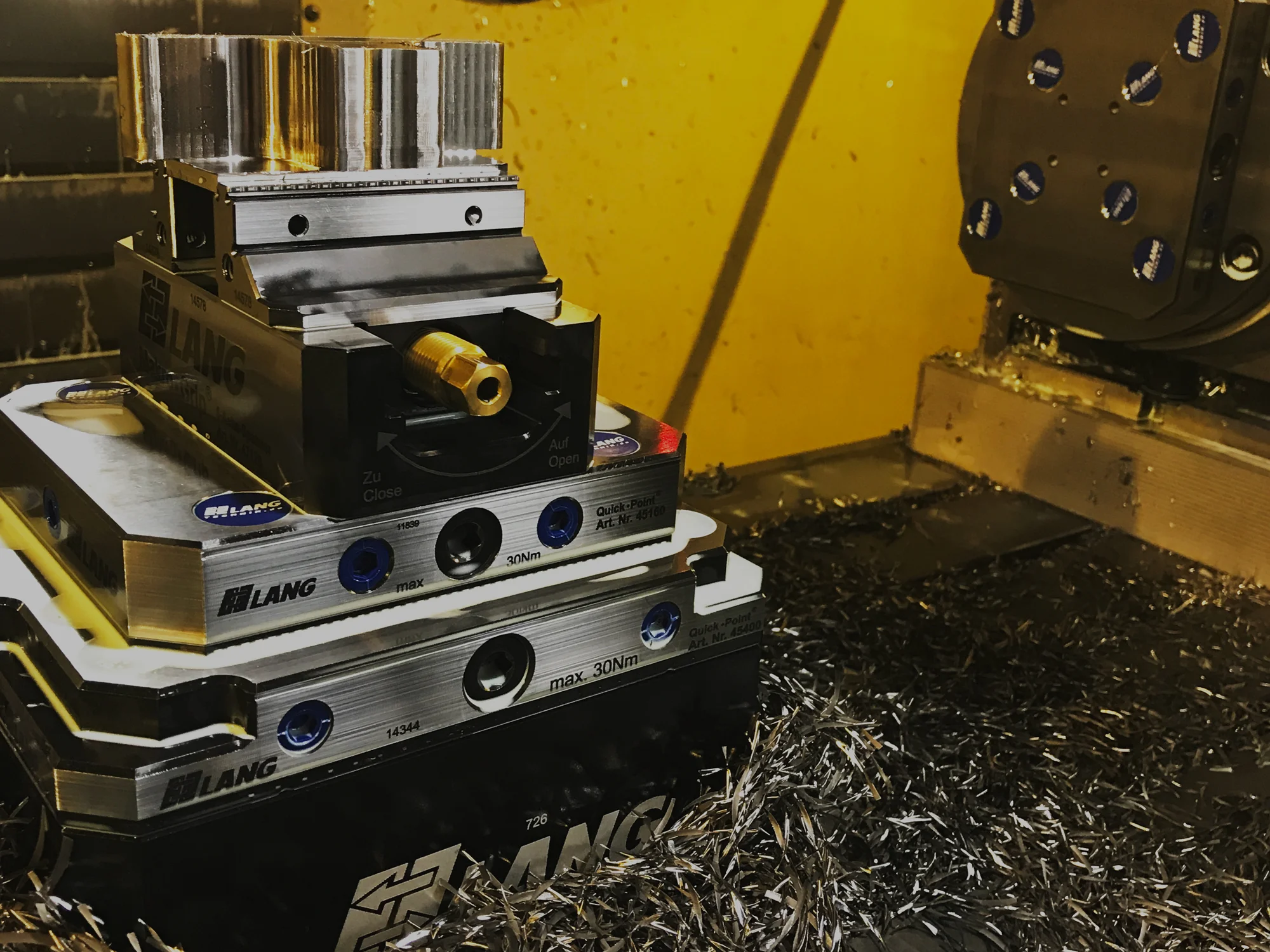

We Specialize in working hand in hand with our customers and engineers to work through critical design / intent features of your parts to ensure you receive exactly what you’re after. We utilize Siemens NX Cad/Cam which allows us to make changes on the fly with little no loss of time during a revision or update. Vertically integrated programming and Lang modular tooling allows IMG to get your parts up and running on in a matter of hours not days. IMG has made a name for itself by taking on the challenge of parts other choose not to quote. Our processes for making one off and R&D runs is streamlined into a proven processes. When it comes to Production, our experience with building custom fixture will shine. We put a great deal of thought into the manufacturing processes and build fixtures to take advantage of our 3, 4 and 5 axis machines and have them running “ lights out “ in order to reduce cost. We use full G code machine simulation to optimize cnc machine run time and effectiveness of our tooling.

IMG has made parts for the following industries utilizing many different materials.

Materials:

Aluminum

Brass

Copper

Kovar

Epoxy Glass

Invar

Stainless Steel

Steel

Titanium

Variety of Plastics

Many More!